Low Energy Electron Accelerator (ebeam)

Expert in grain sterilization using EBeam technology

EBeam Star Technology specializes in low-energy electron accelerator mobile sterilization and disinfection technology, providing efficient, safe, and residue-free toxin elimination solutions for grains such as peanuts, corn, and wheat, ensuring food safety.

Trusted by multiple agricultural enterprises

Safety Standard

National Certified

About EBeam Star Technology

Focusing on agricultural product safety, using technology to safeguard food security

Using Technology to Ensure Agricultural Product Safety

EBeam Star Technology, founded in 2021, is a high-tech enterprise specializing in the research and application of low-energy electron accelerator mobile sterilization and disinfection technology. We are committed to providing efficient, safe, and environmentally friendly sterilization solutions for the agricultural sector.

Our core technology has significant effects on eliminating aflatoxin (AFB1), vomitoxin, and zearalenone (ZEN), and is widely used in the disinfection and sterilization of crops such as peanuts, corn, and wheat, ensuring food safety from the source.

Professional Team

R&D team composed of nuclear technology and agricultural experts

Advanced Technology

Low-energy electron accelerator core technology

Safe & Eco-friendly

No chemical residues, green environmental treatment solutions

Customized Service

Customized treatment solutions based on crop characteristics

EBEAM Technology

Low-energy electron accelerator technology, redefining agricultural product sterilization standards

Low Energy Electron Accelerator Technology

An electron accelerator is an electromagnetic device that uses artificial methods to accelerate electrons in a vacuum under magnetic and electric forces to achieve high energy. We focus on the application of low-energy electron accelerators in agricultural product sterilization.

Technical Advantages

Low Energy Characteristics

Uses electron beams with energy between hundreds of kilovolts and several megavolts, with penetration and energy transfer more suitable for agricultural product preprocessing needs

Self-Shielding Design

The equipment itself can effectively block electron beam radiation, reducing radiation risks to operators and the environment

Precise Control

Can precisely control the energy and dose of the electron beam according to different agricultural product needs, improving treatment effectiveness and quality

Eco-friendly & Sustainable

No chemicals needed during treatment, reducing environmental pollution and resource consumption

Low Energy Electron Beam Sterilization Principle and Advantages

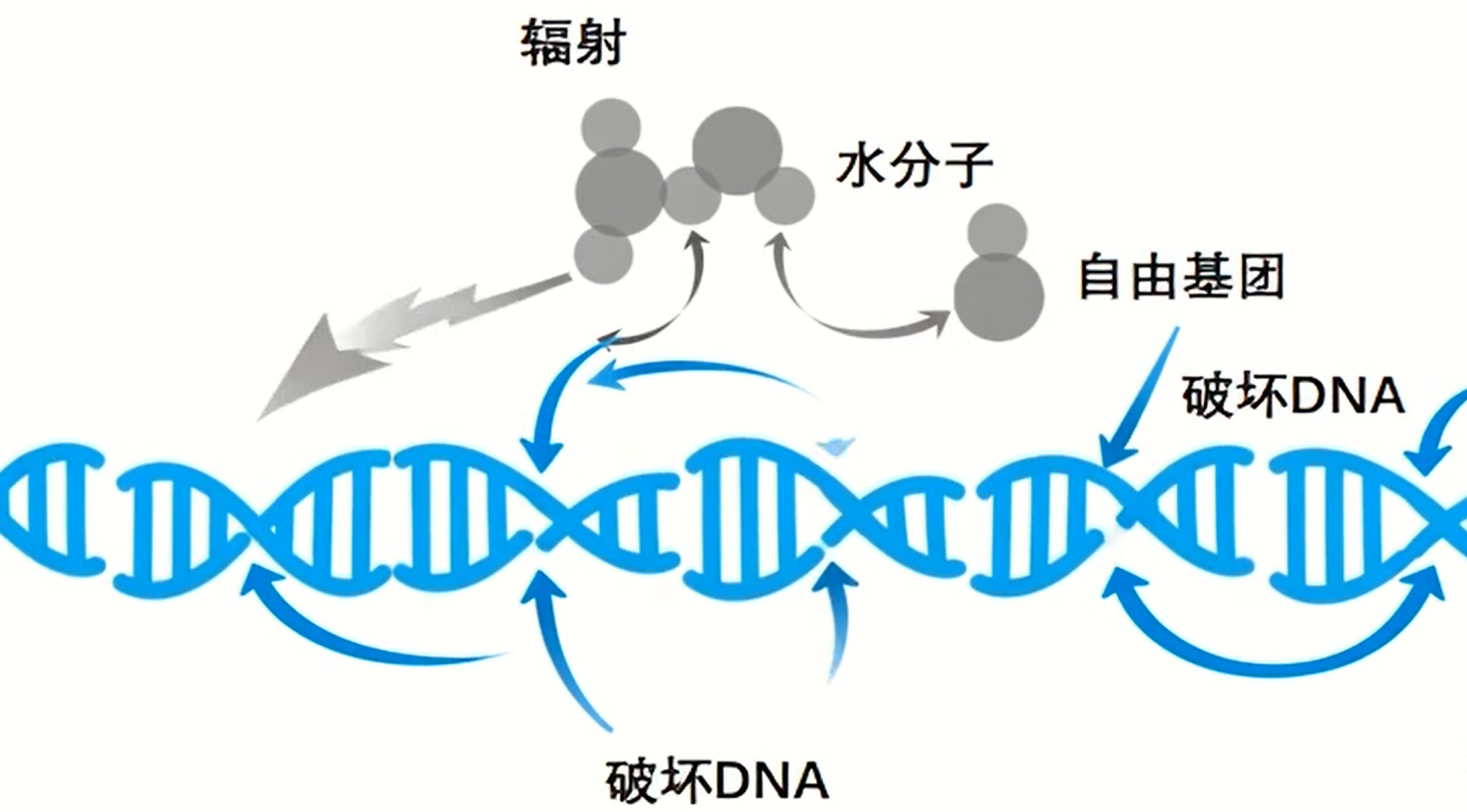

Sterilization Principle Explained

γ-rays/electron beams ionize water molecules in microbial cells, and the generated free radicals undergo oxidation-reduction reactions with ribonucleic acid, proteins, and enzymes, thereby killing microorganisms. This process is achieved through two pathways:

- 1. Indirect Damage: Radiation causes water molecules to decompose and produce free radicals, which then destroy the DNA structure of microorganisms

- 2. Direct Damage: Radiation acts directly on microbial DNA, causing DNA strand breaks, ultimately leading to microbial death

This technology can effectively remove various harmful substances such as aflatoxin (AFB1), vomitoxin, and zearalenone (ZEN), fundamentally ensuring agricultural product safety.

High Efficiency

Rapidly kills microorganisms, significantly reducing processing time and greatly improving production efficiency

Uniformity

Electron beams can be uniformly delivered to all parts of the object, ensuring comprehensive Sterilization with no dead zones

Safety

No need to add chemicals, no residues produced, harmless to the environment and human health

Quality Preservation

Almost no impact on the nutritional content and texture of grains, maintaining original quality and taste

Low Energy Electron Accelerator Solutions: Comprehensive Grain Sterilization

Comprehensive solutions for agricultural product sterilization and disinfection needs

Grain Feed Processing

Effectively removes mold toxins from feed, improves feed safety, reduces animal disease risks, and enhances breeding efficiency.

Port Inspection & Quarantine

Quickly and efficiently processes imported and exported agricultural products, kills harmful microorganisms and pests, meeting international trade quarantine standards.

Grain Warehouse Storage

Comprehensive sterilization treatment before new grain storage, preventing mold during storage, extending storage time, and ensuring grain quality.

Crop Seed Sterilization

Sterilizes seeds, removes pathogens, improves seed germination rate and disease resistance, ensuring healthy crop growth.

Contact Us

Whether you have technical inquiries or cooperation needs, you can contact us through the following methods